SWMS, HRCW & HSRs

HSRs should be involved when a SWMS is prepared for HRCW.

Who doesn’t love an acronym?

Let’s start with some definitions...

SWMS stands for Safe Work Method Statement. This is a document which must be prepared before any HRCW commences. It sets out how the HRCW is going to be carried out at the workplace. It includes an outline of the hazards involved and what control measures are to be put in place to control the risks.

HRCW stands for High Risk Construction Work. It is defined in Regulation 322 of the Occupational Health and Safety Regulations 2017 :

In this Part, "high risk construction work" means any of the following construction work—

(a) where there is a risk of a person falling more than 2 metres;

(b) on telecommunications towers;

(c) involving demolition;

(d) involving the removal or likely disturbance of asbestos;

(e) involving structural alterations that require temporary support to prevent collapse;

(f) involving a confined space;

(g) involving a trench or shaft if the excavated depth is more than 1·5 metres;

(h) involving a tunnel;

(i) involving the use of explosives;

(j) on or near pressurised gas distribution mains or piping;

(k) on or near chemical, fuel or refrigerant lines;

(l) on or near energised electrical installations or services;

(m) in an area that may have a contaminated or flammable atmosphere;

(n) involving tilt-up or precast concrete;

(o) on or adjacent to roadways or railways used by road or rail traffic;

(p) at workplaces where there is any movement of powered mobile plant;

(q) in an area where there are artificial extremes of temperature;

(r) in, over or adjacent to water or other liquids where there is a risk of drowning;

(s) involving diving.

“Construction Work” means "any work performed in connection with the construction, alteration, conversion, fitting out, commissioning, renovation, refurbishment, decommissioning, or demolition of any building or structure, or any similar activity."

So, what role can HSRs play when it comes to SWMS?

Health and safety representatives play a key role in the safety of their workplaces, including in relation to SWMS:

- As with all Health and Safety matters, the HSRs can and should be involved if the work affects their designated work group (DWG).

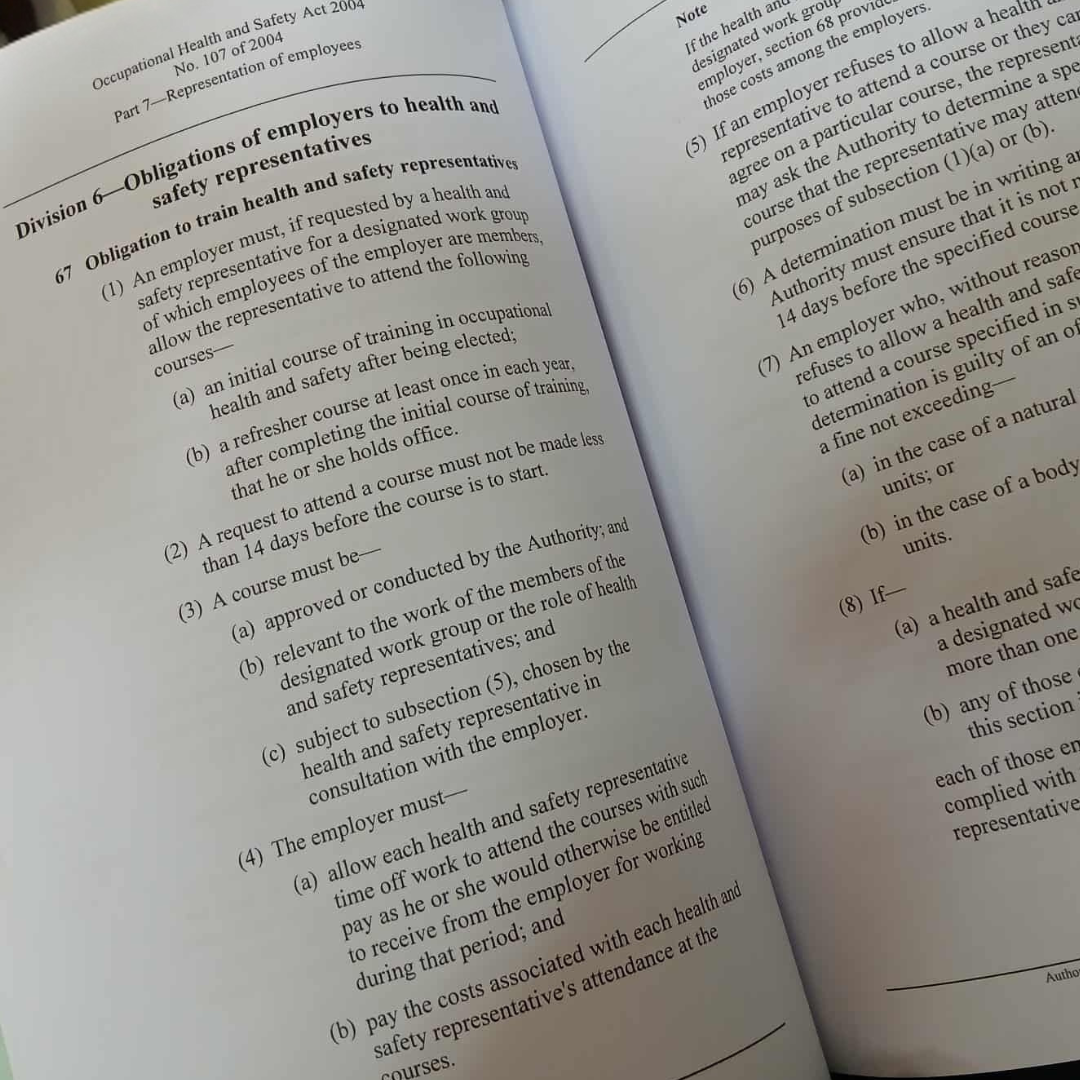

- As part of their legislated duties, the employer must consult with the employees and their HSRs.

- The HSR can play and important role in reviewing the SWMS and raising any concerns from their DWG.

- If conditions change, or if risks are not adequately controlled, then a SWMS must be reviewed. HSR’s are well placed to detect when this is the case and therefore bring this to the attention of their employer.

- HSRs and their workmates in their DWG are the best people to help in designing and reviewing SWMS, as they are the ones actually doing the work.

- They will have hands-on knowledge of how the job is done, any relevant site-specific factors, what hazards and risks are present, how best to control them and know if conditions change on-site (eg: weather).

- HSRs may also be able to help ensure that their co-workers fully understand the SWMS and are ready to go and do their work safely.

After all, the purpose of the SWMS is to ensure that they are safe while they do their work!

For further reading, there is some great material on this topic at:

Safe Work Method Statements (SWMS) | WorkSafe Victoria